Refinishing Your Brake Rotors and Drums With a Brake Lathe

Check out our guide to the five best brake lathes and quickly get your ride back on the road!

Brake lathes are an essential tool in any automotive shop, and finding the right one can be a daunting task. With so many options available, it can be difficult to determine which product is best suited for your needs.

Fortunately, we have put together this guide to help you make an informed decision when selecting the perfect brake lathe.

We will provide you with all of the information needed to choose the right brake lathe that meets your requirements and fits within your budget. Our comprehensive guide includes tips on how to select a quality product as well as reviews of some of our top picks from leading brands in the industry.

Read on now and find out more about choosing the best brake lathe!

How Mechanicaddicts Chooses the Brake Lathe

With so many brake lathes on the market, it can be hard to know which one is right for you. You don’t want to waste your time or money on a product that won’t work well for you.

Researching and comparing products can take hours of your valuable time, and even then there’s no guarantee that you will choose the best option.

At Mechanicaddicts, we understand how important it is to make an informed decision when choosing a brake lathe. That's why our expert reviewers have done all the research for you! We've compared all the top products on the market so that you can find exactly what works best for your needs - quickly and easily!

Why We Love It

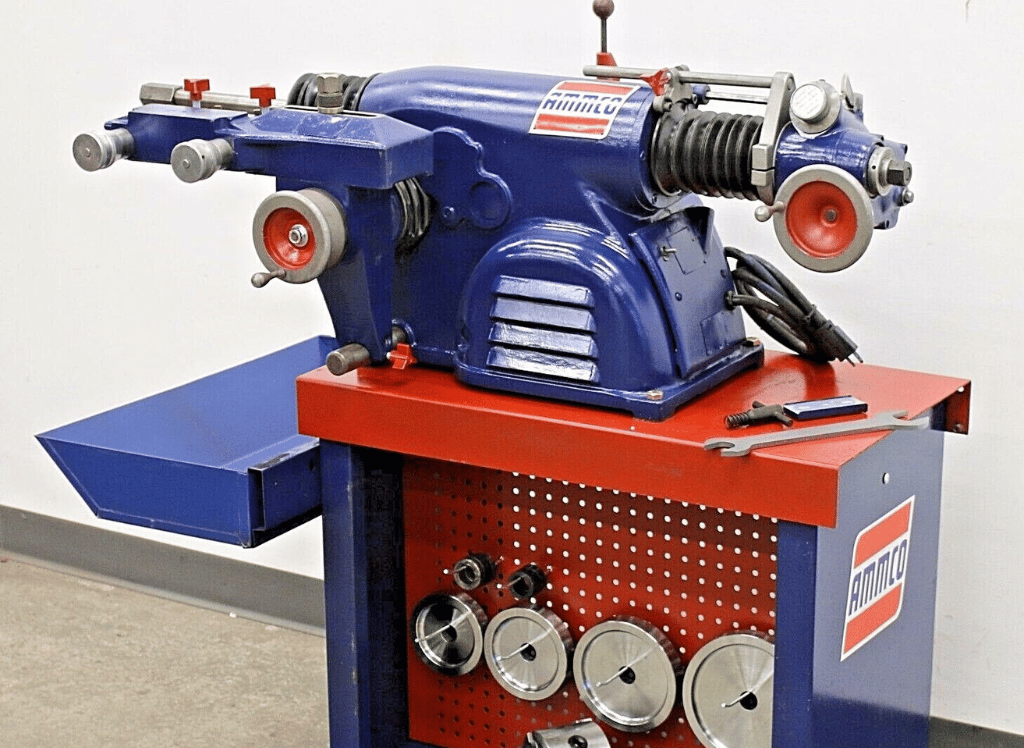

The AMMCO 4000SP Single Pass Brake Lathe is the perfect solution for quick, reliable brake finishing. It features one-pass precision and renowned dependability, so you can rest assured that your brakes will be finished with excellence.

With its accelerated efficiency, this lathe can cut down on time spent working on each job while delivering superior performance. This device is designed to minimize any need for operator involvement and provides a fast and efficient way to complete brake jobs of all sizes. The AMMCO 4000-SP makes it possible to get quality results every time quickly and reliably.

Things to Know

The Ammco 4000SP Single Pass Brake Lathe is a powerful and reliable tool that provides superior performance for brake maintenance. This lathe boasts an impressive cutting system, capable of completing rotor jobs in one pass with a high-quality finish.

With its durable construction, the Ammco 4000SP Single Pass Brake Lathe will deliver professional results time after time.

Why We Love It

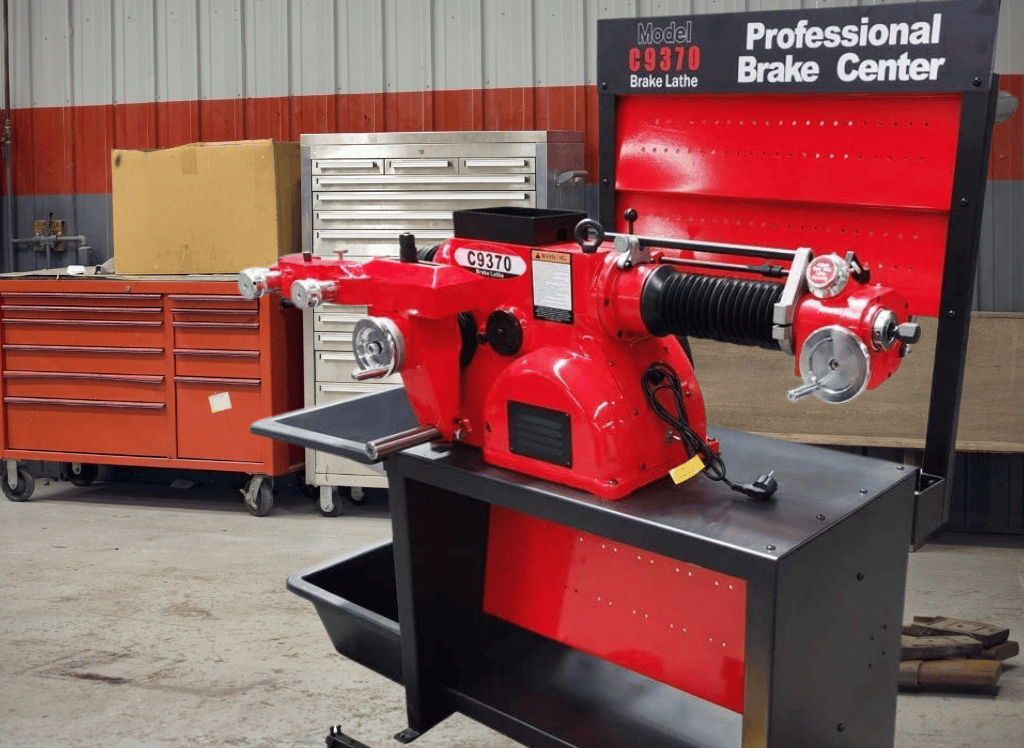

The Kun Ding Heavy-Duty Brake Lathe is an efficient and convenient solution for brake maintenance tasks. It features a quick change tool-head design that allows operators to switch quickly between drums and rotors.

It also comes with upfront controls designed to minimize operator movement, while its bench and top storage tray mean that your most used tools are always close at hand.

Things to Know

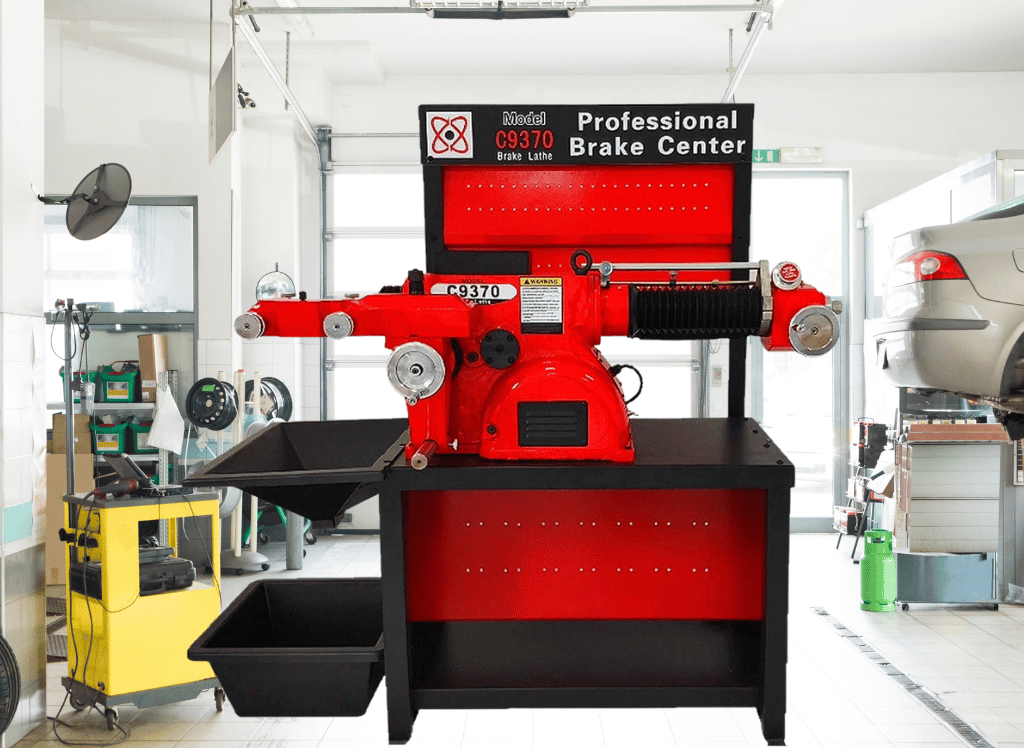

The Kun Ding C9370 Series Heavy-Duty Brake Lathe is an ideal choice for any auto service shop or garage looking to perform brake service. This lathe offers a variety of features designed to make the job easier and faster, including precision cutter tools, quick drum-to-rotor changeover, and positive rake cutter tip angle.

It also boasts a hardened, precision ground spindle that resists grooving and simple ergonomic controls for minimal operator movement.

Why We Love It

The HPDMC Brake Lathe is a reliable and powerful machine designed to handle brake disc operations. It features an impressive decelerate motor with a voltage of 110V/60HZ and 400W power, allowing for maximum discs up to 500mm in diameter and 40mm thick.

This heavy-duty lathe is perfect for cutting, resurfacing, machining slots, grooving drums, and more, offering precise accuracy each time. The HPDMC Brake Lathe promises fast turnaround times while delivering the highest quality results available on the market today.

Things to Know

The HPDMC Brake Lathe is a precision machine engineered for the highest accuracy when cutting brake discs. It features a spindle revolution of 0-200rpm and can operate in temperatures ranging from -20℃ to 40℃.

The cutting accuracy of the brake disc reaches up to an impressive 0.01mm, making it perfect for any high-precision machining job. With its advanced engineering and superior design, the HPDMC Brake Lathe is sure to meet your exacting standards.

Why We Love It

The FPPS Combination Brake Lathe is a simple yet high-performance solution for all your brake maintenance needs. It features a super heavy, hardened, and forged cast iron body which combines with precision ground components and massive "floating spindles" to ensure durability over time.

With the included boring bar, inside floating adapters, self-aligning spacers, adapters, centering cones, and more you won't find yourself at a loss for what you need. The package also includes high-impact anti-vibration bands as well as other essential items such as a 1" arbor and illustrated instruction manual - so you can get started immediately no matter how much experience you have already had.

This lathe is designed to be both easy to operate and trouble-free; ideal for busy shops or individuals that want reliable performance every single time.

Things to Know

The FFPS Combination Brake Lathe is a reliable and efficient tool for servicing brake drums and rotors. Its quick-change tool-head design enables operators to easily switch between drum and rotor setups, while its convenient tooling tray allows them to keep their preferred tools close at hand.

Dual LED lights provide ample illumination of the work area, even in dimly lit shops, while a separate switch offers control over lighting levels. Additionally, included chip catch funnels ensure that debris can be disposed of quickly and conveniently for a more organized workspace.

Why We Love It

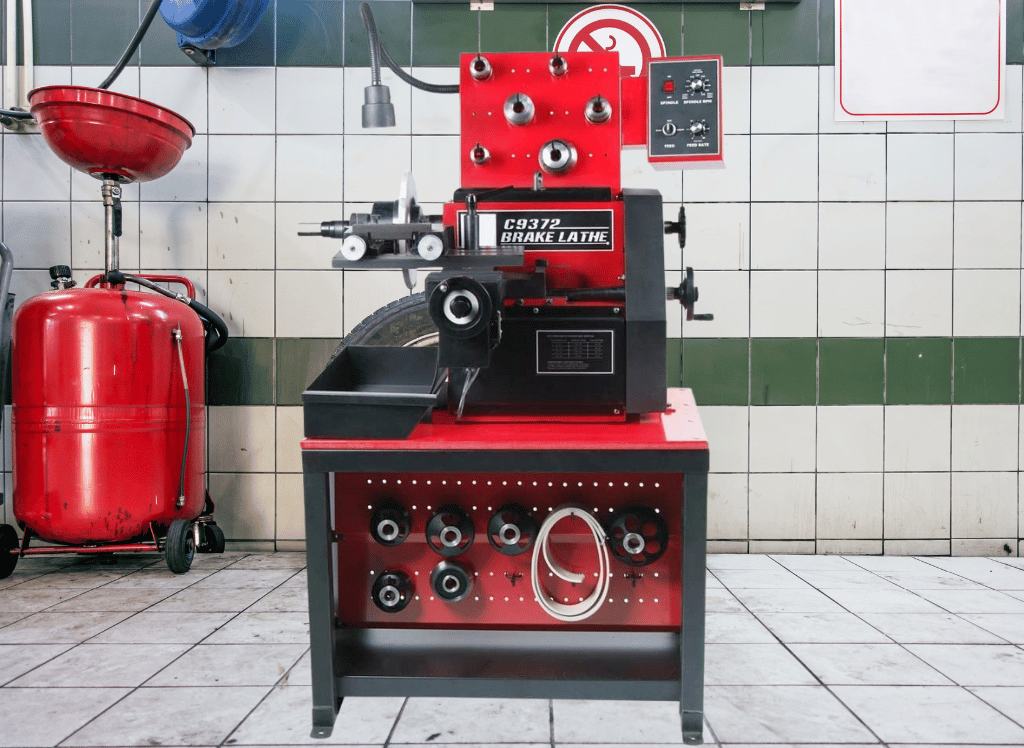

The HPDMC Heavy-Duty Combination Brake Lathe is a complete package for professional brake repair. The quick-change tool-head design allows you to switch from drums to rotors and back quickly and easily, with minimal operator movement.

With the ability to reduce or increase the cut time for the best finish results, this is an ideal lathe package for any workshop. Plus, its convenient top storage tray means that your popular adapters and tools are kept close by. Make use of this powerful machine today and reap the benefits of precise repairs in no time!

Things to Know

The HPDMC Heavy-Duty Combination Brake Lathe C9370 Series is a powerful and reliable tool for automotive service. This lathe features precision cutter tools, quick drum-to-rotor changeover, positive rake cutter tip angle, and more that provide an accurate one-pass finish every time.

The ruggedly constructed components, such as the hardened spindle that resists grooving, ensure accuracy year after year while the simple ergonomic controls are designed to minimize operator movement so you can get your work done quickly and efficiently. It is an essential tool for any garage or shop looking to perform brake service repairs.

Brake Lathe FAQs:

Trying to find the right brake lathe can be a daunting task. With so many options available, it's hard to know which one is best for you and your needs.

Don't worry! We've got you covered with our comprehensive list of frequently asked questions about brake lathes. Now you can purchase your next brake lathe with total confidence knowing that all your questions have been answered!

1. Are Brake Lathes Equipped with Anti-chatter Technology When Resurfacing Car Brake Rotors?

Yes, brake lathes are equipped with anti-chatter technology when resurfacing car brakes. This technology helps to reduce vibration and noise when resurfacing the brake disc and rotor. It also ensures that the brake disc and rotor are resurfaced to the exact specifications, providing a smooth and safe braking experience and will not sacrificing quality.

2. When You Service Rotors Should You Keep the Bench Lathe at a Fixed Speed?

Yes, it is best to keep the bench lathe at a fixed speed when servicing rotors. This will help ensure that the rotors are serviced properly and safely. It is also important to use the correct tools for the job and to follow the manufacturer's instructions for servicing the rotors.

3. Will a Brake Pad Have Uneven Contact If Rotors Are Not Refinished?

Yes, if the rotors are not refinished, the brake pads may have uneven contact. This is because the rotors can become warped or corroded over time, and this can cause the brake pads to make uneven contact with the rotors.

This can lead to decreased braking performance and potentially dangerous situations. To avoid this, it is recommended that the rotors be refinished or replaced when replacing the brake pads.

4. Is There Equipment Needed with the Brake Lathe When Surfacing Brake Rotors and Drums?

Yes, there is the equipment needed when surfacing brake rotors with a brake lathe. The most common equipment needed includes the brake lathe itself, a brake rotor adapter, a brake rotor truing tool, and a brake rotor finishing tool. Depending on the type of brake lathe being used, other specialized tools may be needed as well.

5. What Is an Accu Turn Brake Lathe?

An accu-turn brake lathe is a specialized machine used to resurface and reface brake rotors and drums. It is designed to precisely cut the surface of the rotor or drum to the exact specifications required for optimal brake performance.

The lathe utilizes a cutting head that is driven by a motor and is capable of producing smooth, even finishes on the rotor or drum. This ensures that the brake components are properly machined and that the brakes are operating at peak efficiency.

6. Are Replacement Parts Available for Most Brake Lathes?

Yes, replacement parts are available for most brake lathes. Many brake lathe manufacturers offer a wide selection of replacement parts, including blades, bearings, and other components.

It is important to purchase the correct parts for the specific make and model of the brake lathe you are using. If you are unsure of which parts are compatible with your brake lathe, you should contact the manufacturer for assistance.

Final Thoughts about Brake Lathe

Brake lathes are an essential tool for any automotive repair shop. They provide a precise and efficient method of resurfacing brake rotors, drums, and other components to ensure optimal braking performance.

While there is a wide range of models available on the market today, it’s important to choose one that meets your specific needs in terms of size, power output, features, ease of use, and cost. With proper maintenance and care, you can get years of reliable service from your chosen brake lathe.

#BrakeLathe #AutomotiveRepair #Machining #BrakeService #PrecisionEngineering #VehicleMaintenance #AutoWorkshop #Tooling #LatheWork #BrakeDiscs

Thank you for reading!

Your friend,

Todd

Are you looking for the best products? We've got you covered! Our editors independently selected each item on this list. Mechanicaddicts may collect a share of sales or other compensation (at no cost to you) from links found within these pages if they choose to buy something (that's how we stay in business); as an Amazon Associate, we earn from qualifying purchases. Reviews have been edited for length and clarity; enjoy finding your next favorite thing today!